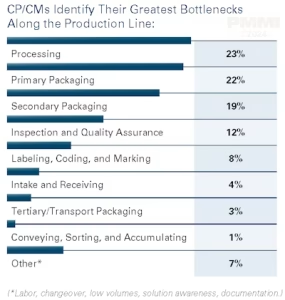

Almost no part of the production line is safe from headaches and holdups for contract packagers and contract manufacturers (CP/CMs), according to PMMI Business Intelligence’s 2024 report, “Contract Packaging and Manufacturing: Drivers of Machinery Investments”. *

Labeling, coding, and marking are identified in the report as areas where bottlenecks can occur, particularly around custom label production and hand application. Bottlenecks can slow down production and lead to delays. Delays can result in unfulfilled customer requirements, loss of business and financial loss.

Automation is one strategy to prevent bottlenecks and keep production flowing smoothly and without interruption. Automating the labeling process begins with determining the most efficient and cost-effective way to print and apply labels. Digital label printing and machine label application are two of the most common automation strategies.

Digital label printing has several benefits that make this an attractive option.

- Reduces lead times

- Eliminates waste

- Ensures a steady supply of labels when needed, at the point of need

- Supports just-in-time production

- Enables short or custom production runs

The foundation of digital label printing is built on three pillars.

- Labeling software that allows labels to be created, updated, shared and managed across the enterprise. Label content changes are made in one place, implemented at once, and available everywhere that label printing happens.

- Digital printing platforms with negligible setup or lead times, are located at or near production, and enable single-pass printing of a complete label, in full color, including variable content.

- Blank labels, stocked at point of use, printed in the exact quantity needed at the precise time of need, with no waste.

Machine label application, also known as auto-application, has distinct advantages over hand or manual application.

- Increases speed and accuracy, enabling greater throughput

- More consistent quality and fewer defects

- Increases production capacity

- Reduces cost while increasing efficiency

Machine labeling solutions are available for any label application scenario. They can be integrated into the production line or implemented as a standalone process. In combination with digital label printing, they help to reduce the risk of bottlenecks that can slow down or even cripple production.

Labeling solutions that combine digital label printing with machine application introduce a level of automation into production processes that give companies the ability to mitigate critical risk factors while creating opportunity to increase capacity and grow their business.

Don’t let labeling be a bottleneck in your production process. Contact Brandywine Label Printing to learn how you can leverage our digital solutions to reduce labeling bottlenecks and drive uninterrupted production!

* Packaging World; Oct. 24, 2024; Co-Mans and Co-Packs See Bottlenecks Across the Packaging, Processing Line